Adeno Associated Virus Vector Manufacturing: Case Studies and Success Stories

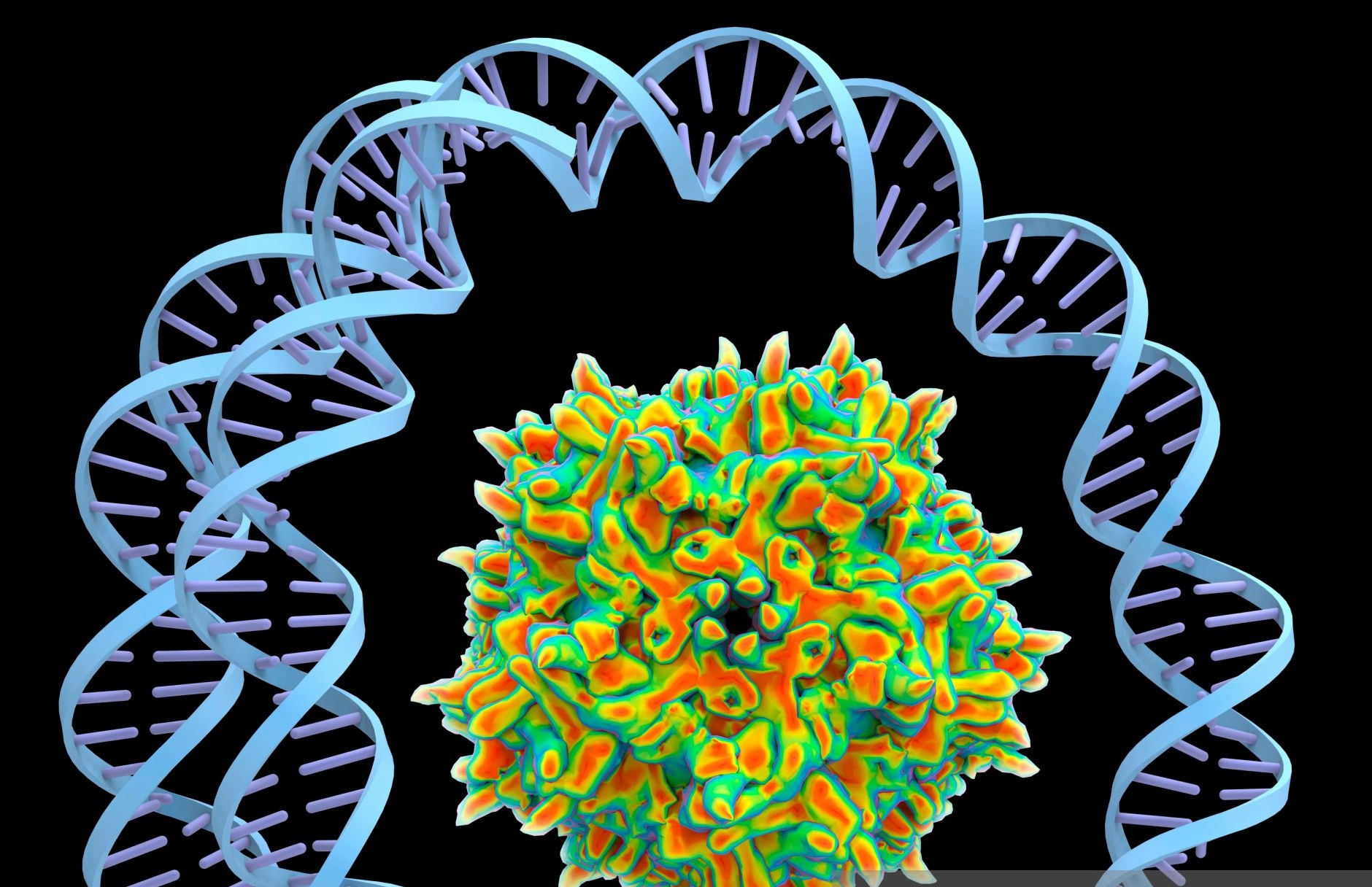

Adeno-associated virus (AAV) vector manufacturing is a critical process in the field of gene therapy, where AAV vectors are employed to deliver genetic material into cells. These vectors are particularly valued for their safety and efficacy, being non-pathogenic and capable of long-term gene expression without integrating into the host genome. The manufacturing process of AAV vectors involves several sophisticated steps to ensure high purity, potency, and safety, which are essential for clinical applications.

The manufacturing process begins with the generation of AAV vector plasmids containing the therapeutic gene of interest. These plasmids are then transfected into producer cells, typically human embryonic kidney (HEK) 293 cells, along with helper plasmids that supply the necessary viral replication and packaging proteins. The transfection can be performed using chemical methods like calcium phosphate precipitation or more advanced techniques such as electroporation. Following transfection, the producer cells generate and assemble the AAV particles, which are subsequently harvested from the cell culture.

Purification of Adeno-associated virus (AAV) vector manufacturing is a critical and challenging step, aiming to remove impurities such as host cell proteins, DNA, and empty capsids (AAV particles without genetic material). Common purification methods include density gradient centrifugation, ion exchange chromatography, and affinity chromatography. Among these, affinity chromatography using an AAV-specific ligand has become a preferred method due to its high selectivity and efficiency.

Quality control is integral throughout the manufacturing process. Techniques such as quantitative PCR (qPCR) and next-generation sequencing (NGS) are employed to ensure the correct genetic material is packaged within the AAV capsids. Additionally, assays like enzyme-linked immunosorbent assay (ELISA) and Western blotting are used to confirm the presence and integrity of viral proteins. Ensuring the absence of contaminants and verifying the ratio of full to empty capsids are also critical quality control measures.

Scaling up Adeno-associated virus (AAV) vector manufacturing production from laboratory to clinical and commercial scales presents additional challenges. Bioreactors and advanced cell culture systems have been developed to increase the yield of AAV vectors, while maintaining quality and consistency. Regulatory compliance is another crucial aspect, necessitating adherence to Good Manufacturing Practices (GMP) and stringent guidelines set by health authorities to ensure patient safety.

In conclusion, AAV vector manufacturing is a complex and multifaceted process that underpins the success of gene therapy. Advances in this field continue to enhance the efficiency, scalability, and safety of AAV production, paving the way for innovative treatments for a range of genetic disorders.

https://www.marketdigits.com/a....deno-associated-viru